Then remove the old compressor and install the new one making sure the marks line up again.

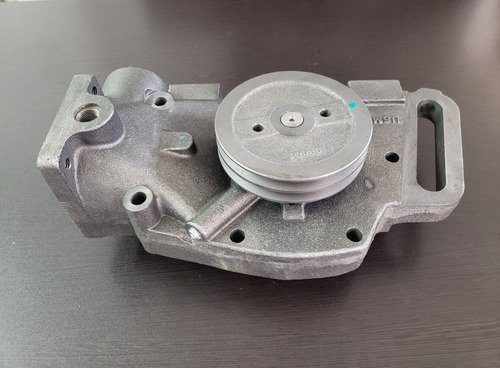

Then you had to watch in that small hole while turning the engine over until you could see the timing marks on the compressor drive gear and the cam gear lined up. Behind it in the front cover of the engine there was a 3/8 pipe plug that you needed a, I believe, 5/16 square drive socket to remove. If the crank was bad in the compressor and you needed to replace it first you would remove the accessory drive pulley. You could actually work the rod for the compressor over the end of the crank without removing from engine. On those older engine with the one piece accessory shaft/compressor crankshaft if you were replacing a Cummins single cylinder compressor it was common to get a reman compressor with no crankshaft. Newer engines had the two shafts splined together making it much easier to replace a bad compressor.

Some of the older engines had the crankshaft for the compressor that was one piece with the shaft that the accessory pulley mounted on. The compressor drive gear has timing mark on it as the marks on the accessory pulley on the front of the engine has the marks you use when setting injectors and valves. Can't talk to big Cams but the small cams all did have the air compressor "timed" to the engine but NOT so it would run right.

0 kommentar(er)

0 kommentar(er)